Partner Content: Dow's Daniella Souza Miranda explains how designing for recyclability, reusing and repurposing can ensure plastic retains its value and helps contribute to a circular economy.

Yes, the demand for a circular economy in the plastics industry is real. Recent research shows that in the last 12 months nearly half of European consumers claim to purchase less products packed in plastic than they used to, and 55 per cent of Spanish consumers made a brand choice (in the last year) specifically for the packaging used.

From a regulatory perspective the European Commission has made a political commitment that all plastic packaging must be reusable or economically recyclable by 2030. And, even in regions where regulations have not yet come in, many major brand owners such as Unilever and Mars have set ambitious 2025 packaging targets.

As a leader in the sustainability space, I understand first-hand the importance in meeting the increasing demands from consumers, brand owners and regulators for sustainable and circular products. Our Transform the Waste initiative, which our business unit is responsible for achieving, commits to delivering three million metric tons of circular and renewable solutions by 2030.

This goal is tough, but achievable. In order to meet our target, and address the plastic waste issue, we are committed to building industrial ecosystems to collect, reuse or recycle waste, and to grow our portfolio of technology and partnerships to help us innovate.

Innovation is key to helping achieve plastic transformation targets. We must think of new ways to develop and commercialise new technologies and processes to improve plastic recycling and recyclability across:

-

- Design

- Production

- Manufacturing

- Recycling

- Collection

Out of these five steps I see design as the most important to improve a circular economy in plastics. To achieve a circular economy, we must start with design. At Dow each new packaging project we work on prioritises the concept of design for recyclability.

Thinking about Design: what is the role of brand owners in designing for recyclability?

Design for recyclability means designing with circularity in mind from the beginning, ensuring materials can be recovered and reused to make new products without compromising performance or functionality at any stage.

At Dow, our plastics are used in a variety of applications; from packaging to building, construction and infrastructure materials. For decades we've been designing our applications to use as few resources and material as possible, as well as enabling reuse and recycling without compromising performance or functionality.

Now, more than ever, our industry has a responsibility to work with brand owners to consider the whole lifecycle of their product when thinking about packaging. Operating as a middle ground between the plastics industry and consumers, brand owners must place recyclability and circularity at the forefront of every decision, from materials and shape to colours and labels.

Maintaining a circularity mindset may sound quite simple, but it's not without challenges. There is a growing need for more options that don't compromise on aesthetics or functionality. Plus, with the upcoming regulatory changes coming from the EU Commission brand owners require more and more circular packaging within an increasingly short timeframe. Working hand in hand with innovators like Dow, brand owners must find a way to meet the ambitions of policymakers, whilst achieving their own ambitions efficiently and cost effectively.

Design Innovation: what options are out there for brand owners looking to embrace new materials?

Brand owners that are serious about design for recyclability will need to embrace innovation in a variety of ways. They must be open to new technologies, compositions, and materials to ensure their products can be recycled as part of a circular economy.

Mono materials are a brilliant example of material innovation currently supporting the progression towards a circular economy:

- Mono materials in packaging means a single film is provided with multiple functionalities e.g. colouring, labelling or barrier qualities to increase the preservation of contents by mixing multiple materials

- Other packaging uses multiple films with each layer being used for a different function

Mono materials have great appeal for brand owners because each material does not need to be separated during the recycling process, ensuring the product is more likely to be recycled by the end consumer.

I believe that for brand owners to gain confidence in new materials and innovations, the opportunity to collaborate, test and learn is key. Dow Pack Studios, our innovation centres which are spread across the world, give brand owners the opportunity to trial, conceptualise and develop new packaging solutions on site. Placing brand owners front of mind, Pack Studios ultimately accelerates packaging innovation by enabling brand owners to quickly bring-to-market sustainable solutions in a dynamic and demanding world.

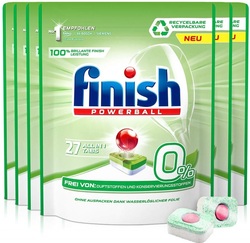

Dow, Drukpol and Reckitt collaborated at Pack Studios to create a re-closable dishwasher pouch. The mono-material Polyethylene (PE) packaging was produced on existing equipment offering budget efficiencies; and thanks to the design for recyclability innovation the entire packaging can be recycled, ensuring consumer appeal. The pouches were successfully piloted and commercialised with FINISH dishwasher tab packaging.

Beyond the right design: ensuring access to waste, and the technology to transform it, to provide a truly circular solution

Designing for recyclability is a core function of circularity. However, for packaging to be truly circular, there also needs to be effective recycling infrastructure and technologies in place to secure and transform waste into circular and renewable solutions.

There are several types of recycling in use today and they largely fall into two complementary technologies: mechanical recycling and advanced recycling. We continue to invest heavily in both technologies to scale them so we can ensure we have the steady supply of recycled and renewable content we need to enable more sustainable packaging solutions.

-

- Mechanical recycling allows us to take back a limited range of waste plastic that is then cut up and re-formed into different plastic products. This currently accounts for more than 99 per cent of recycling volumes in Europe and typically works best for simpler types of plastics, such as rigid plastic bottles. Despite its global importance, there are limitations to mechanical recycling. For example, this approach cannot easily recycle many types of food packaging into new applications because of contamination issues and stringent food safety regulations.

- Advanced or chemical recycling complements mechanical recycling and converts used plastics into their original molecular form. Advanced recycling can recycle harder to recycle plastics including flexible packaging and food packaging. Through this process, raw material can be used as an equivalent of virgin plastic to create new products that can be recycled again and again. This process allows us to take a far greater range of plastics waste back, much of which has low value and would otherwise be incinerated or go to landfill.

Mechanical and advanced recycling have paved the way for strong progress towards a circular economy. However, when considering the raw materials traditionally needed to create plastics, the plastics industry is always looking for new ways to reduce dependence on virgin fossil feedstocks. One of main challenges is the issue of securing a stable supply of waste to create alternative feedstocks that are sustainably sourced. An increasingly viable solution to this challenge is to use food and agricultural waste as certified bio-feedstocks, to allow us to plastic with significantly reduced CO2 emissions.

Bio feedstocks are exciting. They show us that solutions to the plastic waste issue can be found in unexpected places. Sustainably sourced and certified bio-feedstocks means we can leverage other industries' bio residues at scale (ensuring they don't compete with the food chain) and allows us to make plastic with significantly reduced CO2 emissions. Giving us the potential to be large contributors to a circular economy.

Through bio-based feedstocks, Dow is enabling brand owners to advance their journey towards a circular economy. Recently, we have been collaborating with Crocs integrating a new bio-based material into their shoes. This partnership has seen us convert sustainably sourced waste and by-products from other industries into a plastic feedstock. The process has a lower CO2 impact because the technology uses a bio-based ethylene glycol as feedstock, which is made from renewable resources, as opposed to a virgin feedstock.

Conclusion

At Dow we know that by designing for recyclability, reusing and repurposing, we can ensure plastic retains its value and helps contribute to a circular economy.

Through investment in new products and emerging technologies, we're continuing to find ways to make this possible, but we can't do it alone. The entire industry - from brand owners to the wider value chain - need to keep recyclability in mind to ensure that:

- When a product is designed it has the ability to be able to be recycled

- When a product is created it contains a mixture of recycled and/or renewable content

Working together, across industries and throughout the supply chain we can make a circular economy in plastics a reality.

Hear more from Daniella Souza Miranda about how Dow is designing with recyclability in mind, by listening to Dow's Plastics Unwrapped podcast.

This article is sponsored by Dow.